Nickel is an unique silvery-white steel that is primarily used to make alloys stronger and better. It was first determined in 1751 by a Swedish drug store as well as mineralogist, Baron Axel Fredrik Cronstedt.

Stainless steel MIG wire -based items have a lot of significance in our daily lives. Compared to other materials, nickel-based items are harder, a lot more immune to corrosion, and have higher toughness at both low and also high temperatures. Not to fail to remember, it likewise possesses a variety of special electronic and magnetic properties. It is due to these factors that nickel is utilized in most alloying aspects, layers, batteries, and various other important things.

In this guide, we will cover nickel welding cords as well as their uses and performances. If you are fascinated to learn more concerning this distinct metal, offer this write-up a read.

What is nickel welding wire?

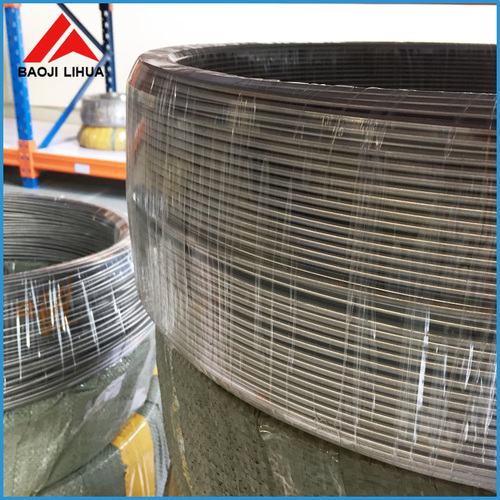

Nickel welding wire is likewise called nickel welding rod. It has a very high demand on the market because of its special high qualities. Nickel welding wires are warm resistant, corrosion-resistant, and can be used under low temperature levels also.

The very best feature of nickel and also its alloy is that it is easily weldable. Nonetheless, you are needed to clean it right away after welding it. Nickel welding cable is mainly used in aerospace, waste therapy, nuclear applications, petrochemical, chemical handling, and so on

. Nickel welding cables are preferred for their crack-resistant plating as well as welding. So you understand Nickel is a non-ferrous steel with high strength. It is likewise immune to high temperatures. This is why it is extensively made use of in industries that require materials with high longevity.

Nickel is a highly flexible steel that is utilized in numerous areas and also markets. As a result of its corrosion and warm resistance qualities, it shows to be an extremely valuable metal.

Use Nickel Welding Cord.

Now that you have a concept concerning nickel welding wire, allow’s discuss its usages thoroughly. Being a versatile steel, nickel has a variety of uses.

1. Alloying aspect.

As pointed out above nickel is a fantastic alloying aspect due to its top qualities. You will find nickel in a lot of alloys. It can be made use of with steel, lead, copper, light weight aluminum, cobalt, gold, and silver.

Nickel is additionally made use of to make long lasting elements like cast irons, stainless-steel, Monel, Inconel, Incoloy, nimonic and also various other alloys..

Speaking of alloys, they can be of 2 kinds including ferrous alloys as well as non-ferrous alloys. The previous consist of stainless steel, cast irons, and some other specialty steels. These items are made use of in chemical plants, gas turbines, aquatic engineering, as well as cash.

Regarding non-ferrous alloys are concerned, it consists of copper alloys such as nickel brasses, monel, and bronzes. These items find their usages in propellers, hulls of tugboats, fishing boats, crankshafts, as well as various other functioning boats.

Nickel-based alloys include Ni-base rust immune alloy, Ni-base superalloy, Ni-base form memory alloy, Ni-based accuracy alloy, Ni-base wear-resistant alloy, as well as Hydrogen storing alloy. These alloys are commonly used in shipbuilding, aeronautics, electronics, the chemical industry, energy sector, and also medication. On the other hand, nickel powder is utilized for powder metallurgy alloys.

2. Batteries.

Nickel plays a vital function planned of batteries. It is a vital part of rechargeable battery systems that are used in power devices, electronics, emergency situation power supply, and also transportation. It is likewise made use of in nickel-metal hydride (NiMH).

3. Welder Metals .

Nickel coatings refer to electroplated nickel. This sort of finishing is utilized to supply hard-wearing as well as ornamental finishings.

When nickel finish is used with a top layer of chromium, it is called chrome-plating. When combined with silicon carbide it is known as composite plating. You will certainly discover this sort of finish in coins.

4. Other usages.

Nickel additionally has many various other uses. For example, it is utilized as an essential stimulant in lots of important responses such as the reforming of hydrocarbons, as well as the hydrogenation of veggie oils. Besides that, it is utilized in the manufacturing of chemicals, plant foods, and fungicides. Not just that, however it is additionally used for binders, filters, and also extra.

Nickel both in elemental form as well as alloyed kind is important to us. It is a functional steel that has a vast array of uses. It has constantly been an essential metal for several reasons. Additionally, it is made use of in almost all major sectors in the world.

Category: Uncategorized

Benefits of TC4 Titanium Pole for Car.

The usage of a titanium rod in automobiles drew back in the 1950s, after the titanium sector started to grow. As a result of price variety as well as technical factors, the use of titanium in the auto sector has actually not gotten a lot of tourist attraction. With the development of auto energy consumption and criteria set for environmental management, it has gradually become a hot discussion subject that the worldwide steel sector together with the automobile industry pays a lot of hearken to. Titanium is a metal that has numerous one-of-a-kind residential properties and that is the reason it is extensively used by so many individuals around the world. It is certainly versatile because it can be made use of for different objectives..

The surface area of TC4 titanium is not extremely tough. Things, the warmth triggered while doing so will certainly assist in the oxidisation of the product. The hardness is not very reduced. There are numerous advantages as a result of which tv4 titanium pole is made use of for car. The most considerable benefit is that it is somewhat affordable than any other steel. There are much more advantages of using TC4 for a vehicle that you will certainly recognize ahead in this article..

If you want to know the advantages of TC4 titanium pole for autos, continue reading this message till completion as it will certainly take you through all the crucial benefits of TC4 titanium pole for the automobile..

What are the advantages of the TC4 Titanium Rod for cars?.

TC4 titanium metal is a really reliable low-cost alternative that can be utilized for vehicles. Some of the major advantages of TC4 Titanium Rod for Automobile which must be taken into consideration are as complies with:.

1. They have extremely high stamina. Considering the different steel materials, the stamina of titanium negative is nearly the greatest, which can also be made use of as different parts of load-bearing.

2. The TC4 titanium rod has a number of exceptional residential properties and also is the most recommended product for a lot of vehicle parts. It had a great deal of benefits for the car.

3. It has a very high resistance to warmth. You can make it benefit long hours below the 200-650 ° C which is excellent for Hugh temperature level elements.

4. It supplies excellent resistance to frost. It doesn’t produce fragile at a reduced temperature level minimal than -100 ° C.

5. TC4 titanium rod has very good ductility. Parts of various forms can be made from it by the process of warm creating, accuracy spreading, stamping, powder metallurgy, and also various methods..

6. It has a reduced density which is merely 60% when compared to the density of steel. It not just minimizes the mass of the automobile but additionally assists in minimizing the inertia of the parts that relocate at a better rate..

7. It provides high resistance to deterioration which makes it much more better to magnesium, stainless-steel, and light weight aluminum. It can shield versus rain and all other climatic peculiarities. It consists of hydrogen sulfide which assists in minimizing antifreeze moisture. It is excellent for all the tail nozzles in various working conditions existing in the atmosphere..

8. It can be used as a good decorating element. Various decorative products of intense colours can be created by the treatment of oxidation..

9. Miniature modulus of elasticity which resembles 50% steel, greater fatigue strength which is excellent for spring..

10. The coefficient of thermal growth is almost 50% comparable to that of stainless-steel and aluminum which makes it ideal for the engine valve and all various other components..

Besides ER70S-6 welding wire as well as other alloys made use of for automobile, there are different alloys which have a higher resistance versus warmth. They are highly resistant to use and also are very rigid.

The primary benefit of the TC4 titanium rod for the automobile is that it helps in the reduction of gas consumption, improving the transmission of power and performance, sound reduction, vibration reduction, as well as loading elements. weldermetals.com assists in enhancing the durability of the car’s security versus environmental variables. The factors pointed out above are several of the major advantages of TC4 titanium pole for the automobile. You can describe these points for knowing more concerning why TC4 titanium pole is utilized for autos.

Understanding the Basics of MIG Welding

If you are a beginner in the process of welding, after that you require to choose MIG welding. One has to understand the basics before we get started with the whole welding steps..

What is MIG welding?.

The arc welding procedure is the sort of welding utilizing which a solid cable electrode is given as input into a welding weapon and also this helps to sign up with 2 base products by making a point of contact with the weld pool. A sort of shielding gas is additionally given as input through the welding gun and it aids the protection of the weld swimming pool from outside contamination..

MIG is the abbreviation of steel inert gas. In Welder Metals , the arc welding process making use of inert gases is described gas metal arc welding. In other simpler terms, the arc welding process is referred to as gas steel arc welding..

This type of MIG process assists artists, motorsport fanatics, farmers, DIY welders, and also ranchers to produce and repair building processes on different materials. The density of the products can be as much as 1/2 an inch. It is additionally used extensively for upkeep functions. In 308LSi MIG wires to the superb versatility, this particular MIG welding supplies, a lot of individuals like this since it is extremely easy to grasp as well as discover. It is very much easier to utilize when compared to an adhesive weapon. One can guarantee the fact that any person can come to be proficient in MIG welding by cutting through a few of the fundamental suggestions.

What are the fundamental points you need to need to adhere to for the welding treatment?.

There are few basic points one have to adhere to for the welding process. When these suggestions are adhered to, one can obtain the ideal output..

Security procedure.

Safety precedes no matter what. The personnel involved in the process of welding have to ensure they put on the right working apparel to get the process of welding right. Full-length pants that are not cuffed, boots, natural leather footwear, a long-sleeved coat that is fire immune, safety glasses, as well as a skull cap. This listing of safety-related clothing shields the workers from head to toe..

Steel prep work.

The most importantly point before you has to do prior to welding two various metals are that requirement to prepare the two metals. There are particular sort of electrodes made use of in the various other kinds of welding procedures that easily eliminate impurities. The solid MIG cord utilized in the process of MIG welding doesn’t deal with the pollutants extremely quickly. The electrodes used in various other welding processes have a multitude of ingredients that help to combat versus international particles..

The contaminants like oil, corrosion could be cleaned up with the help of a steel brush and also the surface area of metal must be brushed down and also need to be ready prior to you strike an arc in it. You require to clamp the occupational materials like cleansing the metal surface. Any kind of problem related to the electrical supply as well as also influences the welding process. If you intend to ensure the welding refines extremely solid externally of the steel, then you require to see to it the welding equipment is fully penetrating the base of the steel..

Tools Prep work.

It is not just sufficient if you prepare the metal, it is likewise important to prepare the tools deployed in the process of welding too.

These are several of the steps you need to comply with to prepare your devices inspecting cords. The arc welding procedure would certainly require you to examine the cord connections. It must be devoid of any type of type of damages and all the connections should be extremely tight..

Electrode Polarity.

The top priority of the electrodes is really essential in MIG welding. Reverse polarity or DC. Electrode positive is the sort of polarity needed for MIG welding. These links are displayed to the individual as well as they are done inside the equipment.

Gas flows.

The securing gas is what provides the necessary space for inert gas circulation. One needs to keep the circulation rate of the gas. The basic circulation price is anywhere between 20 to 25 cubic feet per hr. If you find any kind of type of leakage in the gas circulation, then you need to use the soapy option on the hose pipe as well as inspect if any bubbles originate from it. In case you find any type of leak in the gas hose, you require to remove it and also try to find a brand-new one..

These are a few of the standard points you require to be knowledgeable about regarding the arc welding procedure. There are other sort of specs like the positioning of the steel as well as the electrode, temperature levels that demand your focus also. Stress levels should be normal. High levels or low degrees can create damage.

Hello world!

Welcome to your brand new blog at Edublogs!

To get started, simply visit your blog’s dashboard, edit or delete this post and check out all the other options available to you.

Like more help?

We can walk you through step-by-step in our guide to getting started with your blog.

Happy blogging!